Technology :: Operating Principles

OPERATING PRINCIPLES OF HIJET SYSTEMS |

The Hijector™

|

The heart of all Hijet Systems is the Hijector™ - a liquid jet ejector of proprietary design.

Basic operating principle of the Hijector™ is a momentum transfer from high-velocity

and high-dispersed liquid flow to gas or vapours, formation of supersonic two phase flow,

subsequent braking of the flow and thus converting kinetic energy of liquid into potential energy of compressed gas.

The most remarkable feature of the Hijector™, that makes it possible to use as a high-performance compression device,

is that a two-phase liquid-gas flow attains a supersonic state at rather low liquid velocity.

This supersonic state occurs as a result of the abrupt drop of the speed of sound in such liquid-gas flow

within a certain range of gas volumetric concentration.

Formation of the supersonic two-phase flow results in two significant physical consequences:

- First, the supersonic zone insulates the mixing zone from high pressure zone located downstream,

and by that there is a key opportunity of getting low pressure zones, which can be utilized for gas suction.

- Second, the supersonic liquid-gas flow at low static pressure has high impact pressure therefore effective

braking of this flow and utilizing its kinetic energy for static pressure buildup make it possible to design

devices with very high compression ratios.

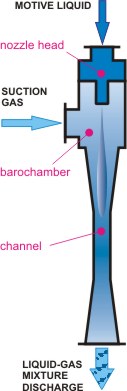

Hijector™ consist of the following core elements:

- Nozzle head for producing a high-velocity and high-dispersed jets of motive liquid.

- Barochamber, where the evacuated gas comes into contact and mixing with the liquid.

- Channel, comprising mixing chamber, throat and diffuser sections, where thorough mixing of the liquid

and gas is taking place with momentum transfer from the liquid to the gas and a supersonic liquid-gas flow is formed.

|

Hijector™ Operation |

|

- Motive liquid under high pressure flows through nozzles into the mixing chamber and at some distance

behind the nozzles forms high-velocity and high-dispersed liquid jets, which mix with entrained gas,

speed up the gas and produce a supersonic liquid-gas flow inside mixing chamber.

- Kinetic energy of the liquid jet is transferred to the entrained gas in the mixing chamber

producing vacuum at the suction inlet.

- Hypersonic liquid-gas flow enters the throat, where it is decelerated by the compression shocks.

Thus low pressure zone in the mixing chamber is isolated from high pressure zones located downstream.

- An irregular subsonic flow is formed behind the compression shock.

The subsonic flow undergoes further braking in subsonic diffuser.

Hijet System Components :

- Discharge from the Hijector™ is separated in a 2-or 3-phase separator.

- A centrifugal or reciprocating pump is used to circulate the motive fluid.

- Heat from near-isothermal compression is removed in a cooler.

- Compressed gas is discharged into pressure lines for clean-up, fuel, venting, instrumentation or other uses.

|

Hijector™ DESIGN |

|

The required parameters of the flow in the channel are provided by accurate selection of the motive liquid,

motive liquid pressure and geometry of nozzles and channel. |

|

Optimal cross-sectional and longitudinal allocation of the liquid-gas flow parameters in the hypersonic zone

of the ejector exerts greatest influence on the performance of Hijector™. |

|

© 1995-2025 Hijet Engineering Ltd |||||